How to stop ice forming in a coolroom and on the floor

Solving the issues caused by air and moisture

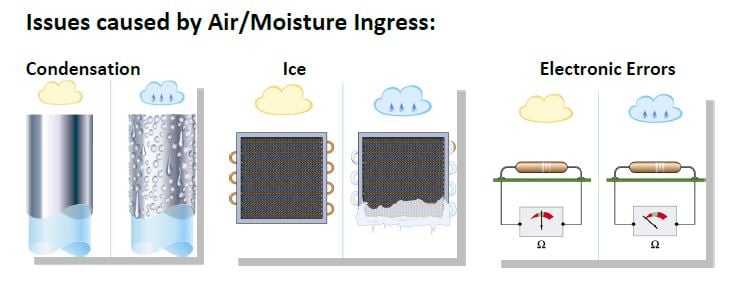

In your coolroom, there are many issues which can be caused by air or moisture ingress. Your doors can also be affected by the infiltration of uncontrolled warm or ambient air. This news post talks about your options for mitigating air infiltration.

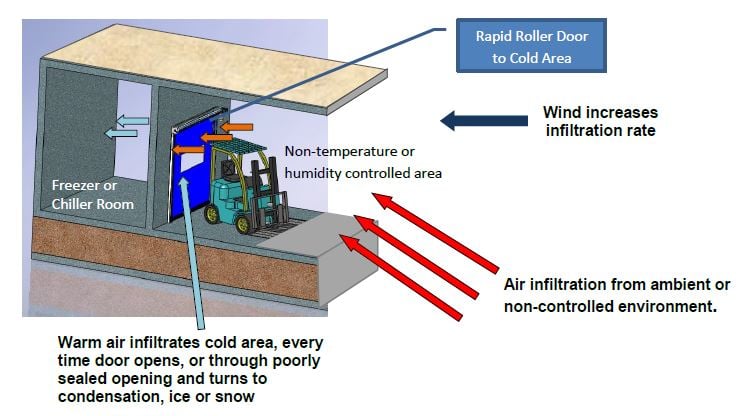

Rapid roller doors are often installed onto freezer and cold room entries to assist with the control of temperature loss or gain through the facility. However you should also consider preventing ingress of warm/moist air through these doorways, when the doors are open or in use, to reduce ice formation in your coolroom and on the floor.

Unless the warm side of the coolroom or freezer is well controlled for temperature and humidity, the ingress of warm or humid air will cause ice and condensation once it reaches your chiller or freezer.

The effect of warm ambient air on coolroom doors

Ice or condensation will form on any surface that is not heated, or is colder than the moisture droplets in the air. This can cause doors to malfunction, and ice / moisture can become a serious slip hazard on floors, not to mention a hygiene issue for food related sites.

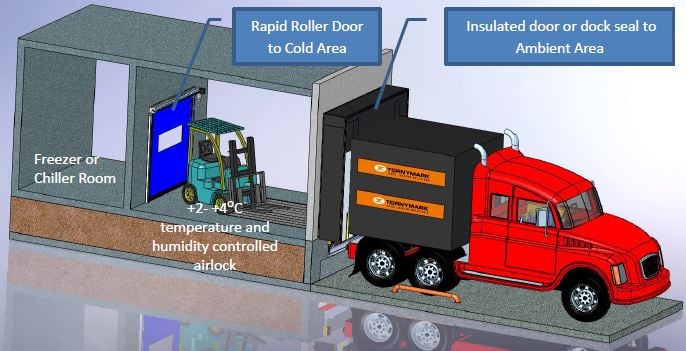

Your facility design options for mitigating air infiltration

- Build air-lock chambers or rooms in front of openings to coldrooms or freezers.

- Control the temperature and humidity in the airlock with additional refrigeration units or air dehumidification.

- Install additional doors between the airlock and ambient areas, and control these to ensure freezer or coolroom doors cannot be opened while an outside door is open.

Preventing air ingress without an airlock

If you do not have an airlock over your chiller or freezer door, and the door opens to ambient, humid air, you will see condensation and ice form on surfaces that are colder than the air coming in. Some options to mitigate these effects can include;

- Install the chiller/freezer door on the warm side of the room. This will ensure that the components of the door are closest temperature to the incoming air.

- Ensure the door blade is insulated. Remax Movichill or Thermic curtains offer an insulated barrier between temperature zones, and reduce the ice or condensation formation on the warm side of the door

- Circulate the air in front of the door opening. By circulating the using air curtains above the door, or wall mounted fans, the warm/humid air is blown away from the cold surfaces and reduces moisture formation.

- Heated frames. By running low wattage heaters in the door frames, you can prevent ice forming on critical parts of the door.

- Heated threshold. By heating the threshold of the door opening, you can reduce slip hazards and melt ice that falls from the door or wall above the opening. Consideration needs to be given to floor drainage for the melted ice/condensation.

- Exclude windows in the door. Windows in rapid roller doors are typically made from PVC which has a low thermal value.

Find out more about preventing ice in coolrooms

Remax's Technical Support team can assist with all your freezer and coolroom door solutions and questions. Call 1800 010 221 to speak to the team or contact the team online today.